This research project aims to develop an automated, reusable formwork technology for free-form concrete construction that integrates economic efficiency, ecological sustainability, and digital manufacturing. The core objective is the development of a fully automated production process for modular formwork elements made from technical waxes, enabling the fabrication of geometrically complex concrete components at industrial scale.

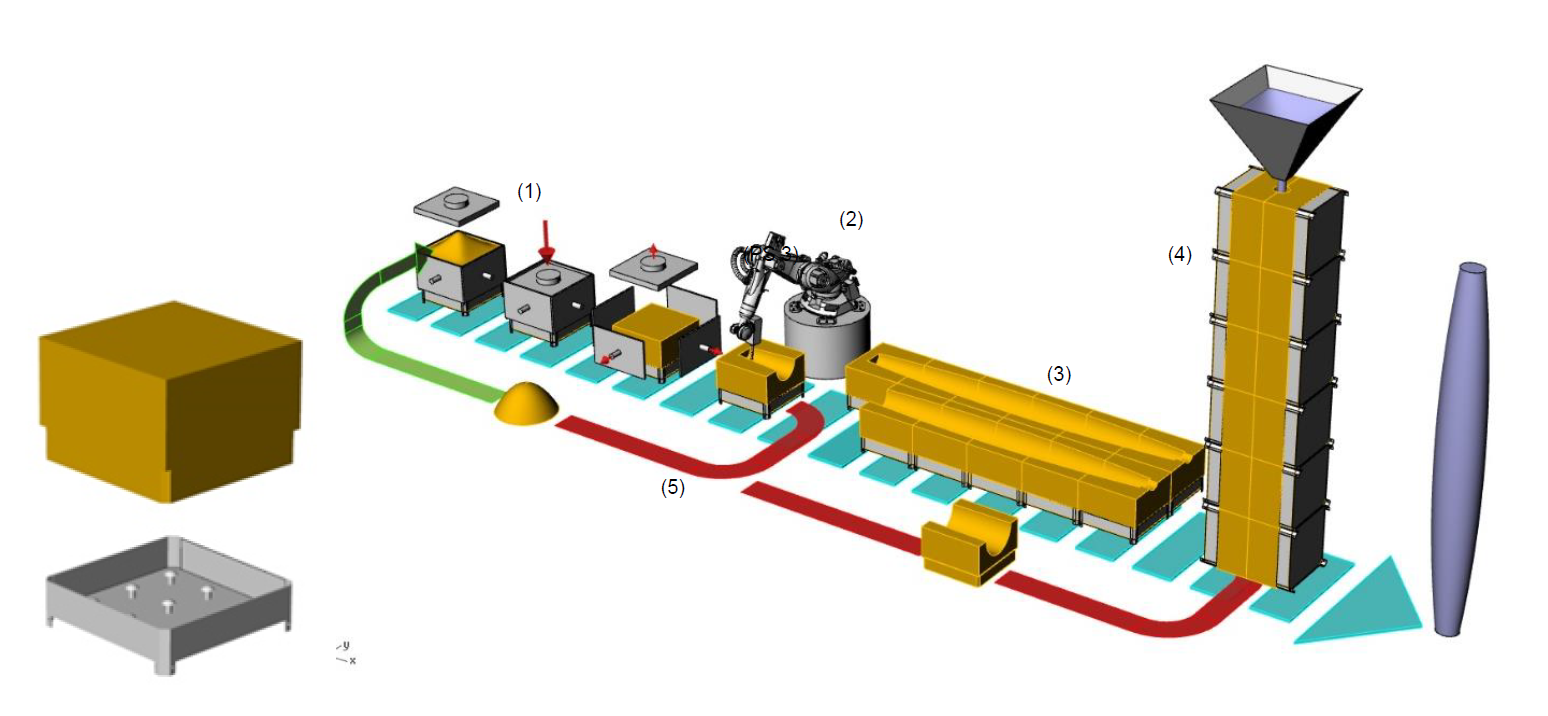

The project focuses on the process and system technology required for mass production of reusable wax-based formwork modules. These modules can be assembled into large-scale formworks with an almost unlimited range of shapes and extensible dimensions. Key research topics include the development of steel carrier plates and connection systems, bonding techniques between wax and structural supports, wax pressing and forming processes, CAD/CAM-controlled machining of wax surfaces, and the implementation of a closed-loop recycling system allowing complete remelting and reuse of the wax material.

By closing the digital workflow from design to fabrication, the research enables precise transfer of complex geometries from digital models into physical formworks. The resulting technology makes advanced digital planning and manufacturing methods applicable to construction-scale production and provides a foundation for integrating structural efficiency, material optimization, sustainability, and architectural freedom in future concrete construction.

Wirth, Franz Wilhelm: Untersuchungen zur Eignung der Non-Waste-Wachsschalungstechnologie für die automatisierte, individuelle Fertigung von Betonbauteilen, 2020 10.24355/dbbs.084-202009110949-0 https://leopard.tu-braunschweig.de/receive/dbbs_mods_00068999 - Dissertation

Franz Wirth is a former colleague of ITE. Please contact Sven Jonischkies, Jeldrik Mainka or Felix Hauser for further information.