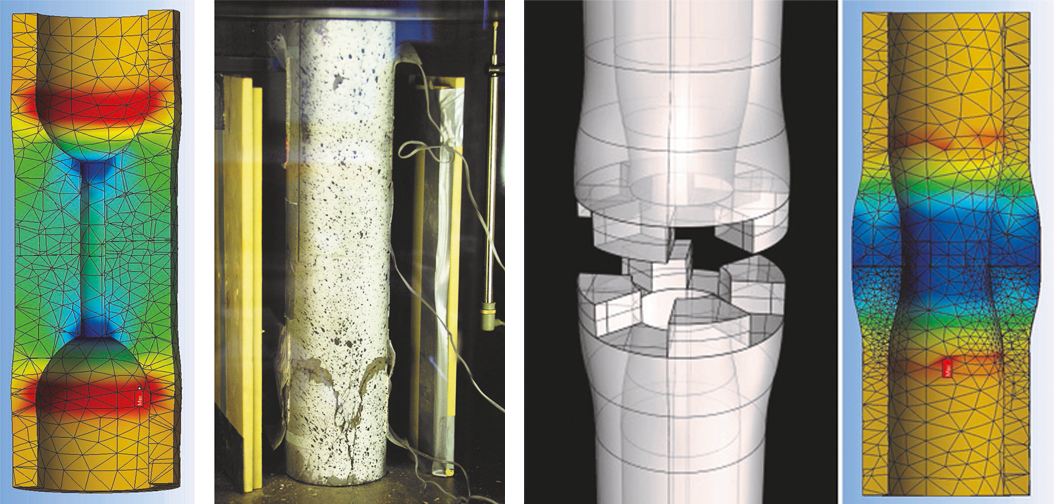

During the first funding period of SPP-1542 “Concrete Light,” ITE and the Institute for Building Materials, Solid Construction, and Fire Protection (iBMB) at TU Braunschweig collaborated on the subproject “Development of novel jointing systems for complex beam surface and spatial elements made of UHPFRC” The focus was on extensive investigations into geometrically complex and high-precision dry-jointed butt connections for thin-walled UHPC components for the transfer of compressive, bending, and shear forces. Steel fiber-reinforced ultra-high-performance concrete (UHPFRC) was used in the research project to improve tensile strength and post-fracture behavior.

The focus of the research in the second funding period was to transform the novel connections for UHPFRC components developed in the first application phase into high-performance lightweight bar, surface, and spatial load-bearing elements. The goal was to increase the load-bearing capacity of components and structures by intelligently coupling individual modular rod and surface elements to form hybrid, interacting load-bearing elements and systems. By combining dry-jointed bars with shear-resistant, flat or curved surface elements, the feasibility of a wide range of structurally relevant structural types, from predominantly flexurally stressed structures to form-optimized shells, was to be demonstrated. The fundamentals of the first funding period were retained:

The use of UHPFRC to improve tensile strength and post-fracture behavior, precisely fitting dry joints, and efficient material utilization through planned prestressing.

Since it was not possible to investigate all conceivable combinations of bars and surfaces in their geometric diversity in this research project, three cases relevant to construction practice were selected from the possible structural element combinations as examples for the work:

Joining of bar and surface elements to form a uniaxially prestressed plate beam element, joining of bar and surface elements to form an orthogonal, biaxially prestressed surface structure (section of a grating), and joining of bar and surface elements to form curved spatial structures.

[1] Mainka, J. et al.: Development of new jointing systems for lightweight UHPC structures. In: Müller, H. S.; Haist, M.; Acosta, F. (Eds.): Proceedings of the 9th fib International PhD Symposium in Civil Engineering, Karlsruhe Institute of Technology (KIT), 22.−25.07.2012, Karlsruhe, Germany. KIT Scientific Publishing, Karlsruhe, 2012, S. 341−348.

[2] Mainka, J.; Lehmberg, S.; Budelmann, H.; Kloft, H.: Non-Standard Fügeprinzipien für leichte Bauteile aus UHPFRC. Beton- und Stahlbetonbau 108 (2013) 11, S. 763−773

[3] Lehmberg, S.: Herstellung und Eigenschaften von dünnwandigen, trocken gefügten Bauteilen aus ultrahochfestem faserverstärkten Feinkornbeton, Dissertation TU Braunschweig, 2018.

[4] Lehmberg, S.; Budelmann, H.: Entwicklung von dünnwandigen Stabwerksknoten aus ultrahochfestem faserverstärkten Beton. In: Breitenbücher, R.; Mark, P. (Hrsg.): Beiträge zur 1. DAfStb-Jahrestagung mit 54. Forschungskolloquium in Bochum, 07.−08.11.2013, Ruhr-Universität Bochum, 2013, S. 47−52

[5] Lehmberg, S.; Ledderose, L.; Mainka, J.; Budelmann, H.; Kloft, H.: Non-Standard Joints for lightweight modular spatial and shell structures made from UHPFRC. In: Brasil, R. und Pauletti, R. (Eds.): Shells, Membranes and Spatial Structures: Footprints, Proceedings of the IASS-SLTE 2014 Symposium, 15.-19.9.2014, Brasilia (Brasilien), 2014

[6] Lehmberg, S.; Mainka, J.; Ledderose, L.; Budelmann, H.; Kloft, H.: Neuartige Verbindungen für geometrisch komplexe Flächen-und Stabwerkelemente aus UHPFRC. In: Scheerer, S.; Curbach, M. (Hrsg.): Leicht Bauen mit Beton – Forschung im Schwerpunktprogramm 1542, Förderphase 1, Dresden: Eigenverlag TU Dresden, 2014, S. 122−139 – nbn-resolving.de/urn:nbn:de:bsz:14-qucosa-171431

[7] Lehmberg, S.; Ledderose, L.; Wirth, F.; Budelmann, H.; Kloft, H.: From Jointing Systems to Light-Weight Structures: Hybrid, dry-fit beam, surface and spatial structures made of UHPFRC. In: KIVI (Hrsg.): Future Visions – Proceedings of the International Association for Shell and Spatial Structures (IASS) Symposium 2015, 17.–20.8.2015 in Amsterdam (the Netherlands), paper No. IASS2015-417738, 8 S., ISBN (Electronic): 978-90-5363-042-6, 08/2015 (published on USB stick)

[8] Lehmberg, S.; Ledderose, L.; Wirth, F.; Budelmann, H.; Kloft, H.: Von der Bauteilfügung zu leichten Tragwerken: Trocken gefügte Flächenelemente aus UHPFRC. Beton- und Stahlbetonbau 111 (2016) 12, S. 806–815

[9] Budelmann, H.; Lehmberg, S.: Von der Küchenarbeitsplatte zum leichten Tragwerk – Was kann ultrahochfester faserverstärkter Feinkornbeton? In: Scheerer, S.; van Stipriaan, U. (Hrsg.): Festschrift zu Ehren von Prof. Dr.-Ing. Dr.-Ing. E.h. Manfred Curbach, Dresden: Institut für Massivbau der TU Dresden, 2016, S. 90–103 (open access)

[10] Lehmberg, S.; Budelmann, H.: Modulare, dünnwandige Plattenbalken aus UHPFRC mit Non-Standard Fügungen. Kurzberichte aus der Forschung, 2016, Institut für Baustoffe, Massivbau und Brandschutz der TU Braunschweig − www.ibmb.tu-braunschweig.de/docpool/reports/KaF-2016-11.pdf

[11] Ledderose, L.; Lehmberg, S.; Wirth, F.; Budelmann, H.; Kloft, H.: From digital design to precise production: Dry-jointed coffered ceiling made of UHPFRC-components. In: Bögle, A.; Grohmann, M. (Eds.): Interfaces: architecture.engineering.science – Proceedings of the IASS Annual Symposium 2017, 25.–28.9.2017 in Hamburg, Hamburg: HCU & IASS, 2017, book of abstracts: p. 124, full paper published digitally: paper no. 9194, 8 pages