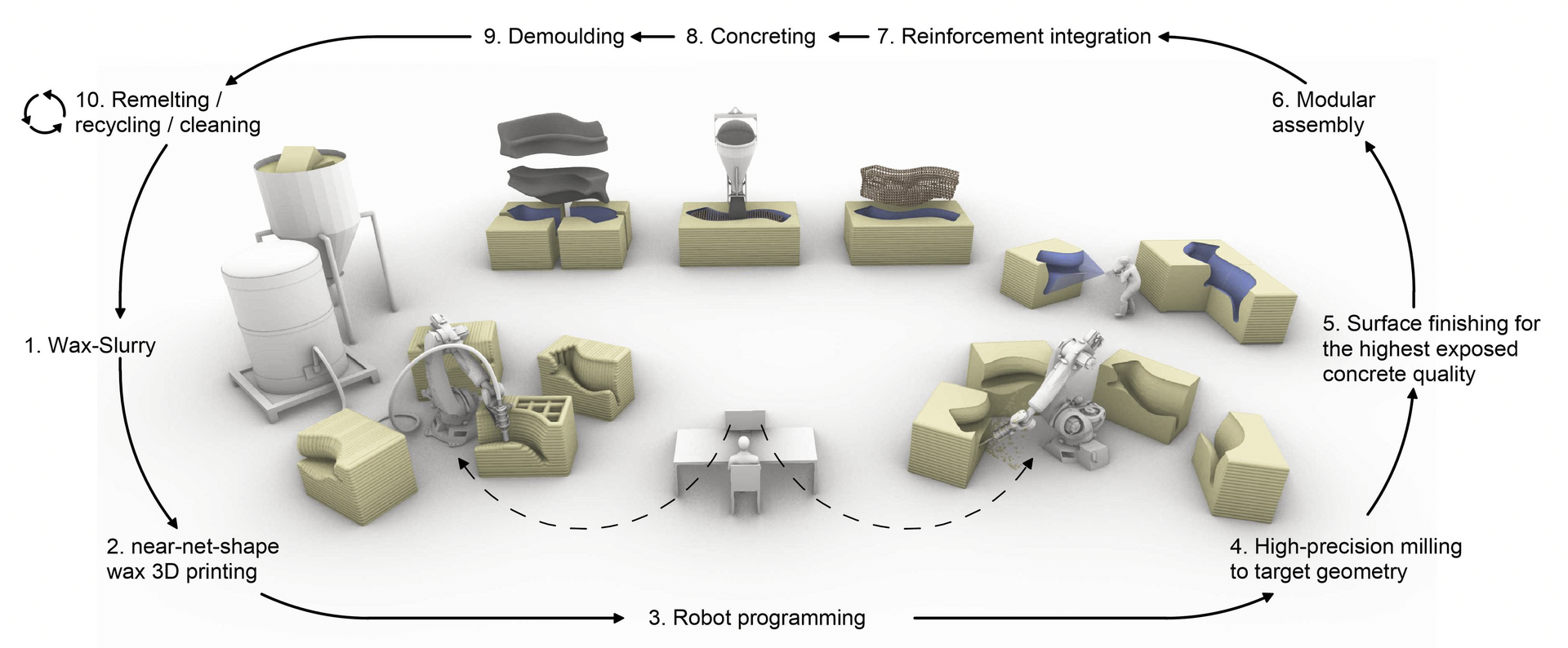

The Wax Foam Formwork 3D Printing research project introduces an innovative wax-based formwork technology that integrates additive manufacturing with subtractive finishing. The process combines the automated production of near-net-shape wax blanks via 3D printing of wax foam with subsequent high-precision CNC milling for surface finishing, all within a fully digital and automated workflow.

Developed through an industrial collaboration between ITE and the candle machinery manufacturer Herrhammer GmbH, the process enables the fabrication of wax blocks that closely approximate their final geometry during printing. These printed blanks are then machined to final tolerance using CNC milling technology. While CNC-based wax milling has been extensively investigated at ITE in several prior research projects, wax foam 3D printing represents a novel and inventive contribution and is currently undergoing the patenting process.

By combining wax foam 3D printing with CNC milling, the hybrid process compensates for the inherent limitations of each individual method, resulting in a highly efficient and precise manufacturing approach. The technology is currently being further developed within a self-financed research consortium, with the aim of industrial implementation in precast concrete plants.

Jonischkies, S.; Hack, N.; Kloft, H.; Mainka, J.; Diesslin, R. (2023). Wax formwork manufacturing device and method for manufacturing a wax formwork (Germany, Braunschweig Patent PCT/EP2023/077722)