This research focuses on Sprayed Earth Additive Manufacturing (SEAM) as a novel digital construction method that combines earthen materials with robotic fabrication. SEAM proposes an alternative to conventional cement-based additive processes by using earth mixtures composed of clay, aggregates, water, and, when required, natural fibres. The approach aims to leverage the environmental advantages of earth—regional availability, recyclability, low embodied energy and CO₂ emissions, while overcoming the limitations of traditional earthen construction, which is often slow, labour-intensive, and difficult to standardize.

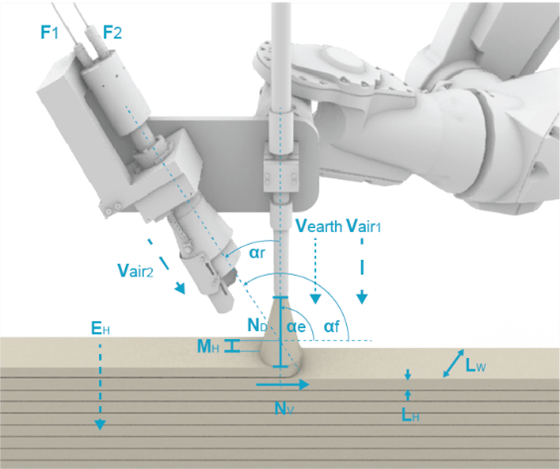

The study pursues two core objectives. First, it investigates the material requirements for SEAM, including the rheological performance of earth-based mixtures. This encompasses the evaluation of pumpability, sprayability, buildability, shrinkage behaviour, and mechanical capacity under compression. Understanding these properties enables the formulation of mixtures capable of being transported, deposited, and layered with precision in a controlled robotic process. Second, the research seeks to design, implement, and validate the SEAM fabrication system at architectural scale. This includes the development of robotic deposition strategies, nozzle geometries, and process parameters suited for continuous layer build-up. Full-scale demonstrators and fabrication experiments will be used to assess geometric accuracy, structural performance, and surface quality, as well as the potential of SEAM to produce differentiated components that combine aesthetics, insulation, and load-bearing capacity. Ultimately, the work aims to establish SEAM as a reproducible and industrially relevant construction technology, demonstrating how digitally controlled spraying of earthen materials can enable faster, more affordable, and environmentally conscious architecture.