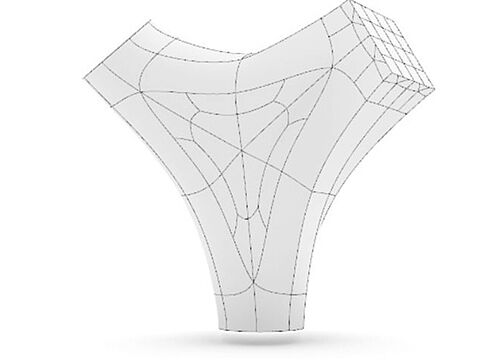

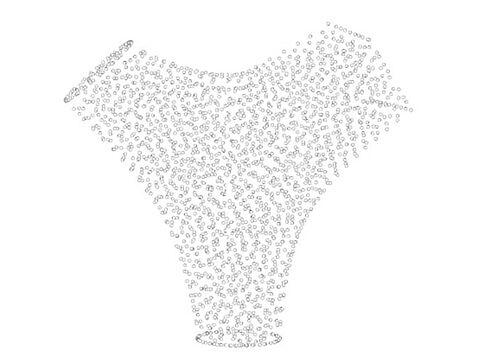

This project deals with the design process of components for additive manufacturing (AM) by Wire and Arc Additive Manufacturing (WAAM). In construction, components are often individual parts and usually used in the building as a single part or in small quantities. With the implementation of AM processes, these components are usually free-form geometries that result from the fulfilment of a wide range of boundary conditions. This includes improvements in material utilization through topology or shape optimization, geometries suitable for production and architectural design requirements. Due to the frequently small number of identical components, the effort required to create the geometry must also be kept low, as otherwise the economic advantages of AM are outweighed by the effort required in the design process.

The approach in this project is to automate as many work steps as possible. As a further guideline, the respective effort per work step should be kept as low as possible. Due to its versatile adaptability, Rhinocerus and Grasshopper are used, as well as specially programmed components in C#.

Müller, J.; Grabowski, M.; Müller, C.; Hensel, J.; Unglaub, J.; Thiele, K.; Kloft, H.; Dilger, K., 2019. Design and Parameter Identification of Wire and Arc Additively Manufactured (WAAM) Steel Bars for Use in Construction. In: Metals - Open Access Metallurgy. Nr. 9 (2019) Vol. 725. Available at: https://doi.org/10.3390/met9070725