This project explores how continuous fibre reinforcement can be integrated into concrete 3D printing to enable structural performance beyond compression-based applications. By introducing automated robotic winding processes, the research aims to unlock material-efficient, structurally optimized, and architecturally expressive additive construction. Replacing conventional steel with textile reinforcement introduces new design and fabrication challenges, but also opens opportunities for lighter, more efficient structural systems.

Three reinforcement strategies—Frame Winding, Core Winding, and Pin Grid Winding—were developed and tested through case studies of increasing complexity. These approaches were applied across different additive manufacturing techniques, including extrusion, material jetting, and particle bed printing. The project addressed the full fabrication chain, from digital element design and robotic path planning to the development of specialized tooling, automated production, and structural evaluation. This allowed the research team to study the interaction of fibres, concrete, and fabrication processes in a systematic way.

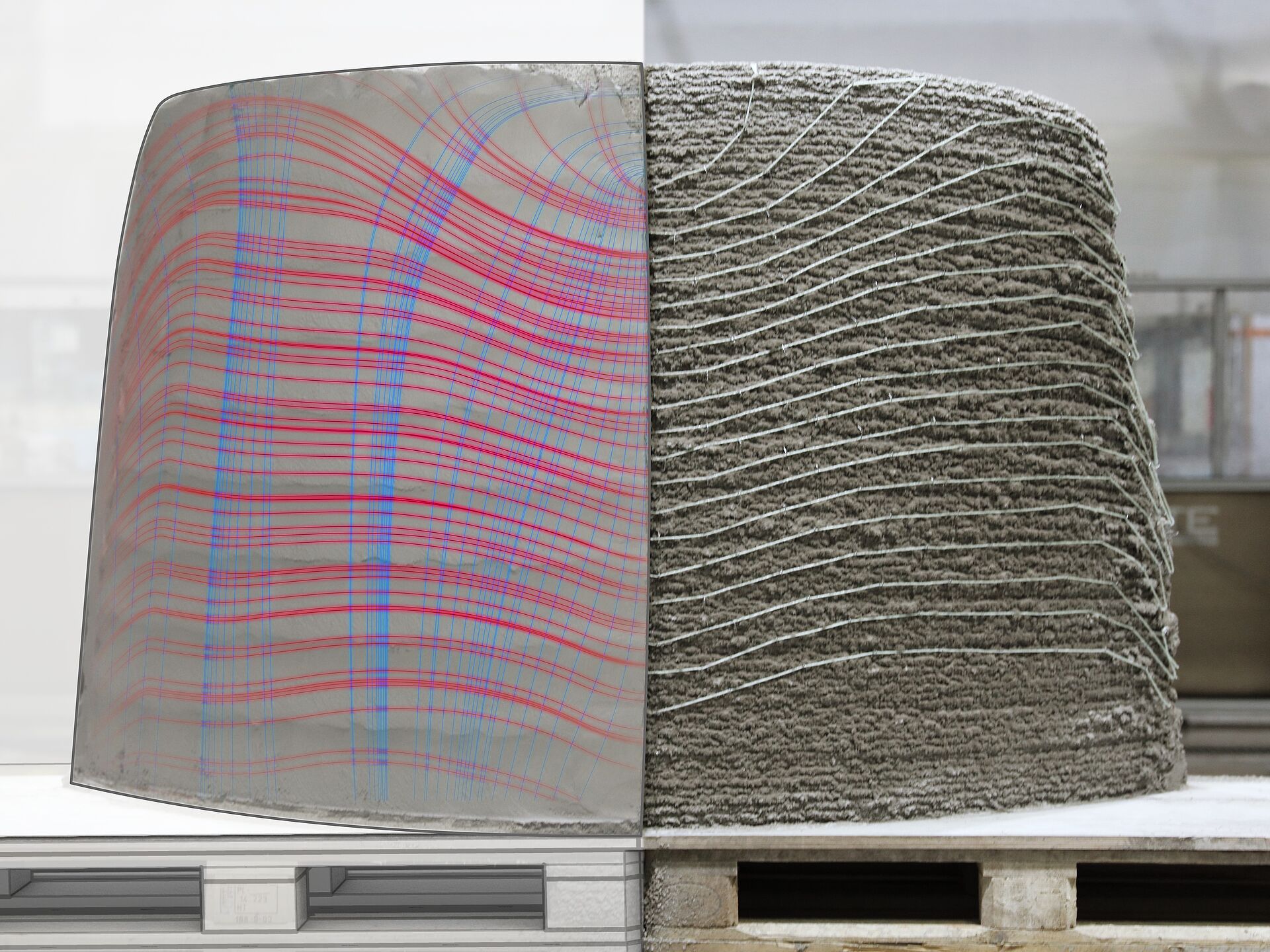

A complete robotic setup for producing individualized fibre reinforcement was realized in the laboratory, including end-effectors and dynamic winding routines. The validated strategies confirmed the feasibility of automated fibre integration and demonstrated high-quality composite behaviour. Frame Winding, combined with Shotcrete 3D Printing, enabled full fibre encapsulation and resulted in a double-curved thin-walled demonstrator. Core Winding showed that complex, force-aligned reinforcement paths can be placed on freshly printed surfaces and embedded with a shotcrete cover layer. Pin Grid Winding allowed the insertion of flat and slightly curved meshes into various techniques such as particle bed printing.

[1] Gantner, Stefan, et al. "Robotic frame winding: prefabricated fibre structures as formwork and reinforcement for digitally fabricated shell-like concrete elements." Construction Robotics 9.1 (2025): 12. doi: 10.1007/s41693-025-00154-0

[2] T. Rothe, J. Pösch, S. Gantner, N. Hack, and C. Hühne, “Optimization of tensile properties and bond behaviour to concrete of fibre reinforcement strands produced within a dynamic fibre winding process,” in 11th International Conference on Fiber-Reinforced Polymer (FRP) Composites in Civil Engineering (CICE 2023), 2023. doi: dx.doi.org/10.5281/zenodo.8133237.

[3] T. Rothe, S. Gantner, N. Hack, and C. Hühne, “A Dynamic Winding Process of Individualized Fibre Reinforcement Structures for Additive Manufacturing in Construction,” Open Conference Proceedings, vol. 3, Dec. 2023, doi: 10.52825/OCP.V3I.187.

[4] P. Rennen et al., “Robotic knitcrete: computational design and fabrication of a pedestrian bridge using robotic shotcrete on a 3D-Knitted formwork,” Front Built Environ, vol. 9, 2023, doi: 10.3389/FBUIL.2023.1269000.

[5] S. Gantner, T.-N. Rothe, C. Hühne, and N. Hack, “Reinforcement Strategies for Additive Manufacturing in Construction Based on Dynamic Fibre Winding: Concepts and Initial Case Studies,” Open Conference Proceedings, vol. 1, pp. 45–59, Feb. 2022, doi: 10.52825/OCP.V1I.78.

[6] S. Gantner, P. Rennen, T. Rothe, C. Hühne, and N. Hack, “Core Winding: Force-Flow Oriented Fibre Reinforcement in Additive Manufacturing with Concrete,” pp. 391–396, 2022, doi: 10.1007/978-3-031-06116-5_58.

[7] I. Mai et al., “Large Particle 3D Concrete Printing—A Green and Viable Solution,” Materials 2021, vol. 14, no. 20, p. 6125, Oct. 2021, doi: 10.3390/MA14206125.

[8] N. Hack et al., “Development of a robot-based multi-directional dynamic fiber winding process for additive manufacturing using shotcrete 3d printing,” Fibers, vol. 9, no. 6, Jun. 2021, doi: 10.3390/fib9060039.