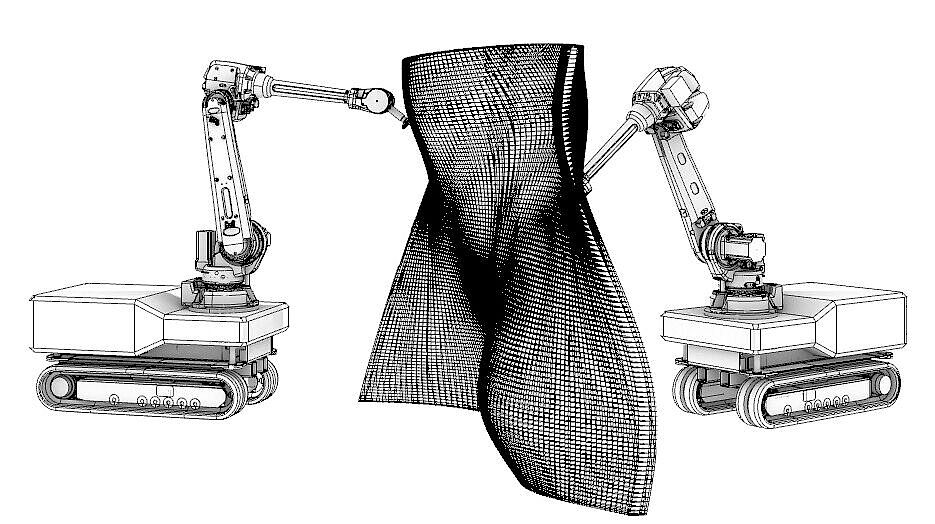

In the second funding period, subproject A05 advances from controlled laboratory prefabrication toward robot-assisted on-site and in situ fabrication of fiber-reinforced, additively manufactured concrete elements. Building on the Dynamic Winding Machine (DWM) and reinforcement integration strategies established in Phase 1, the project now leverages the newly developed Digital Construction Site (DCS)—a cyber-physical large-scale research facility featuring stationary printers, mobile robotic manipulators, augmented reality tools, and comprehensive sensing systems.

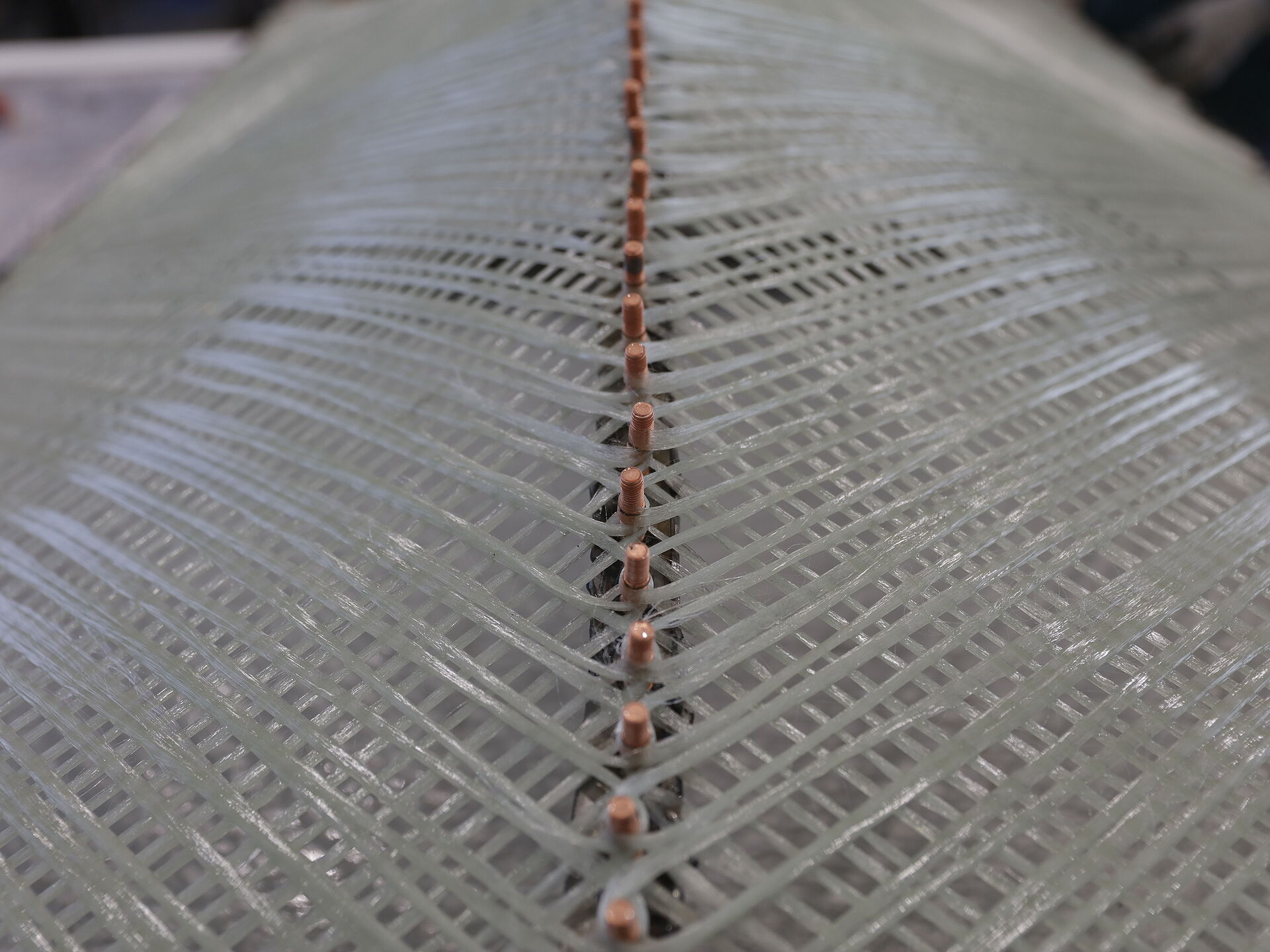

The core objective of Phase 2 is to enable automated, adaptive, and sustainable on-site production of fiber reinforcement under real construction conditions. This includes addressing challenges such as varying environmental influences, complex geometries, variable reinforcement diameters, and multi-robot collaboration. To achieve this, A05 will develop controlled and sensor-supported fabrication processes, transitioning from deterministic workflows to feedback-driven manufacturing. New sensing systems will measure key parameters such as fiber tension, degree of cure, fiber volume fraction, and surface structuring to ensure robust production quality.

Research activities expand the scope from singular components to complex element systems, including multi-element assemblies such as wall–wall or wall–ceiling connections. Strategies for Frame Winding, Core Winding, and Pin-grid Winding will be adapted for on-site use, and corresponding connection logics for integrating multiple additively manufactured elements will be developed

A05 also collaborates closely with projects A03, A04, B05, C06,C05 and C09 to evaluate the sustainability potentials of on-site reinforcement production, including reduced logistics, lower material consumption, and improved working conditions. Phase 2 concludes with a full-scale demonstrator fabricated on the DCS, showcasing an integrated, thin-walled, fiber-reinforced architectural system that validates both structural and ecological performance.