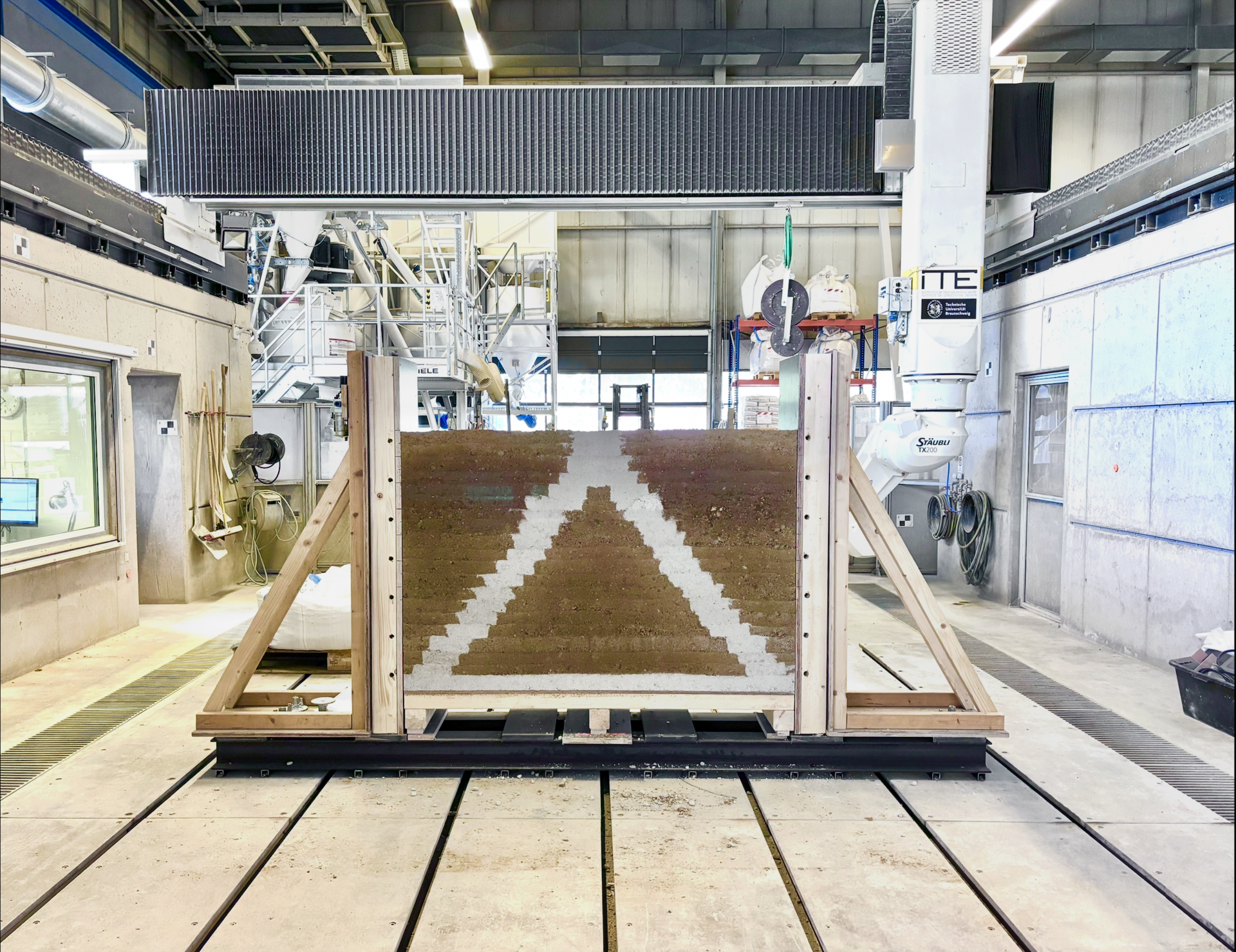

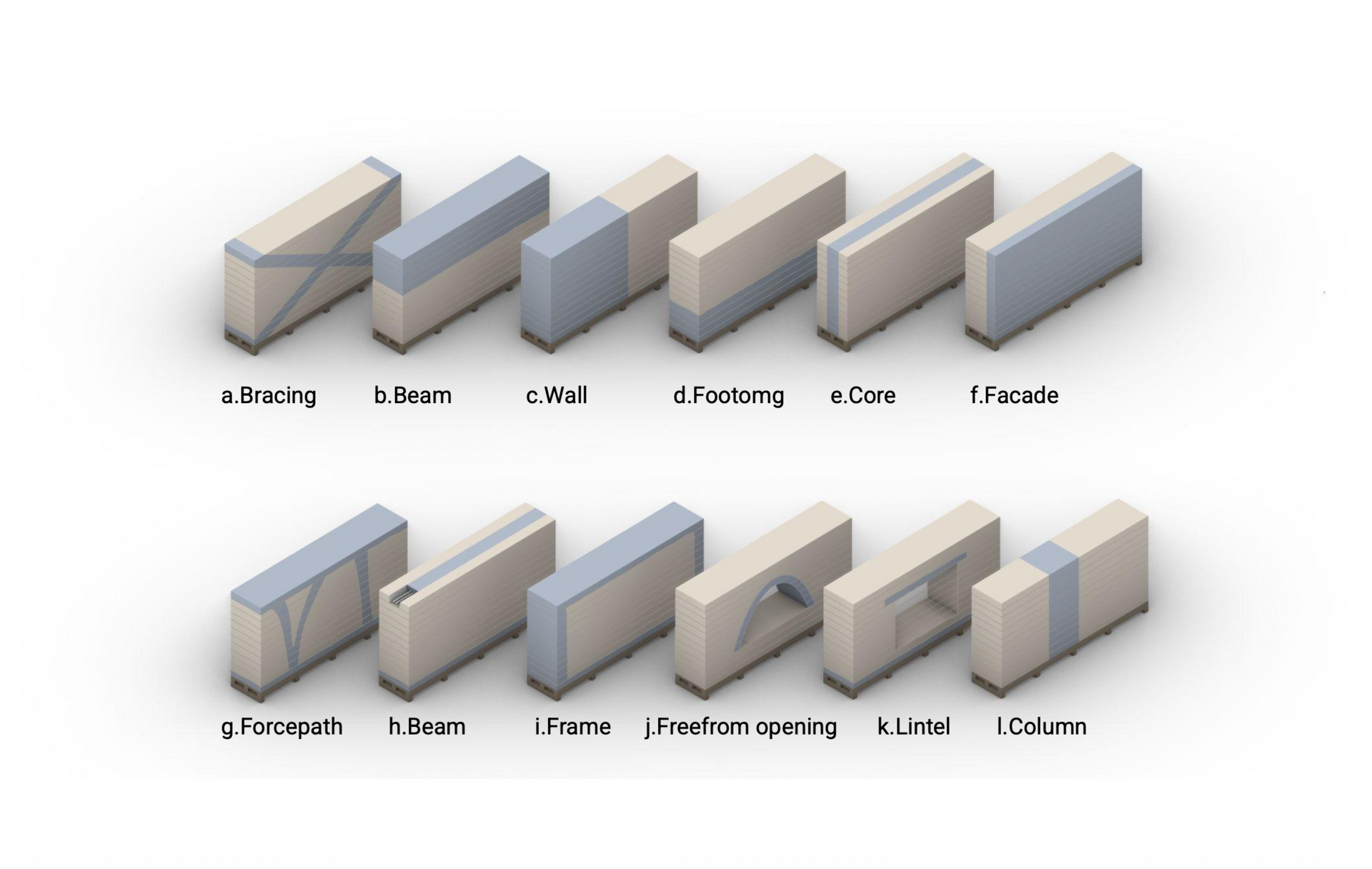

Stampflehmbeton research project explores how rammed earth (RE) and rammed concrete (RC) can be unified into a single fabrication process. Robotic rammed earth is a research previously conducted at ITE, developing tools and automating the rammed earth process. This research project brings the advantages of a single automated fabrication process and material hybridity together. This solution results in a low-carbon building system solution by increasing the performance of RE, while keeping concrete parts separated, in order to prevent soil contamination, and selectively strengthening the RE elements. This project investigates a wide range of parameters, including lab studies on material mixtures and the mechanical performance of each RE and EC recipies combined rammed earth-concrete, while also conducting large scale experimental studies on the fabrication process and compaction parameters, and the material-process interaction influence. Combining the material control and process control solutions, design studies and prototype elements were done to explore and demonstrate how this hybrid solution can be used in a variety of architectural and structural solutions. Stampflehmbeton aims to make climate-friendly building systems more functional and accessible, and to contribute to a broader transformation towards resource-saving, and paving the ground for regionally rooted building culture solutions.

Kloft, H., Salamatian, A., Gosslar, J., Dorresteijn, E. and Lowke, D., 2024, June. Robotic Rammed Earth-Concrete (RREC): A Novel Additive Manufacturing Technology to Strengthen Rammed Earth Structures by Integrated Rammed Concrete Parts. In International Conference on Earthen Construction (pp. 60-70). Cham: Springer Nature Switzerland. DOI: 10.1007/978-3-031-62690-6_7