This project investigates an integrated robotic fabrication method for producing thin-shell concrete elements using prefabricated fiber structures that act simultaneously as reinforcement and stay-in-place formwork. By combining robotic frame winding with a modified Shotcrete 3D Printing (SC3DP) technique, the approach enables the creation of structurally efficient, geometrically complex shell components with minimal waste and reduced material consumption.

Early design exploration involved model-scale experiments in manual fiber winding. These studies provided insights into mesh density, fiber interactions, and sequencing, directly informing the robotic winding logic for the full-scale prototype. Through this iterative process, a hybrid fabrication system emerged that balances computational precision with inherent material behavior.

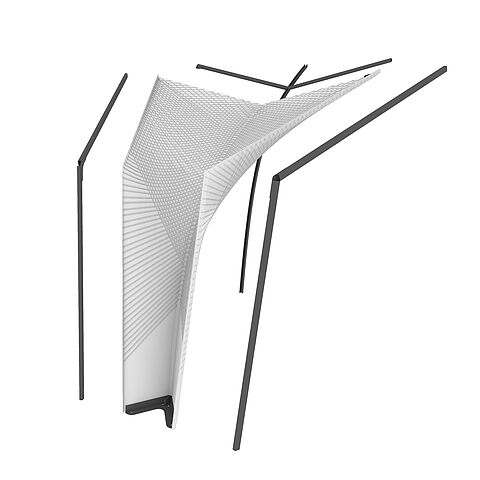

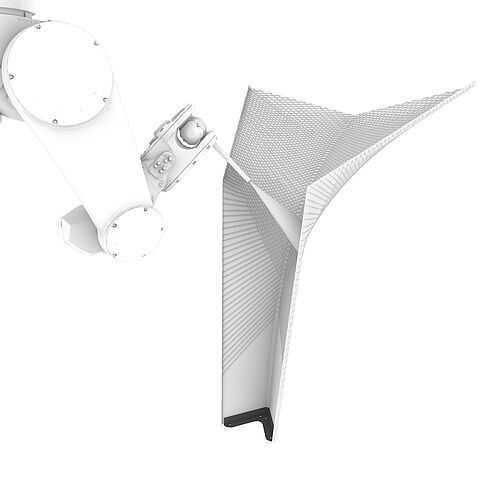

The robotic fabrication was conducted at the Digital Building Fabrication Laboratory (DBFL). A modular steel frame with 3D-printed PETG pins supported the fiber winding process. A custom end effector deposited glass fiber strands and a fleece tape simultaneously. The tape created a continuous yet porous surface that prevented excessive shotcrete penetration while enabling bonding, effectively converting the fiber mesh into a functional formwork.

Shotcrete was then applied using the Robotic Area Shotcrete Printing method, which sprays concrete in controlled thin layers rather than stacking layers. Parametric path planning allowed real-time modulation of nozzle distance and feed rate to maintain consistent thickness and texture. While the concrete remained in its green state, CNC trimming refined the edges to form connection interfaces.

This demonstrator confirmed the viability of integrating robotic winding and SC3DP to create prefabricated shell elements, offering a sustainable alternative to formwork-intensive construction while embedding structural logic directly into the reinforcement system.

Institute of Assembly Technology and Robotics, Leibniz Universität Hannover

Institute of Machine Tools and Production Technology, Technische Universität Braunschweig

Institute of Mechanics and Adaptronics, Technische Universität Braunschweig

Institute of Building Materials, Concrete Construction and Fire Safety, Technische Universität Braunschweig

Chair of Building Technology and Climate Responsive Design, Technical University Munich

Gantner, Stefan, et al. "Robotic frame winding: prefabricated fibre structures as formwork and reinforcement for digitally fabricated shell-like concrete elements." Construction Robotics 9.1 (2025): 12. doi: 10.1007/s41693-025-00154-0