Our mission statement:

"The working group aims to design, understand, control, and optimize complex cyber-physical thermal energy systems so that they can be integrated into alternative vehicle concepts and the 'city of the future'."

Dr.-Ing. Wilhelm Tegethoff

Modeling, simulation, and optimization of cyber-physical complex thermal energy systems.

Dr.-Ing. Nicholas Lemke

Experimental and theoretical investigation of energy-efficient thermal systems and components

The working group researches on battery-electric cars, fuel cell trucks, hydrogen storage and refueling systems, dryers, wastewater treatment plants, heat pumps, refrigeration systems and air conditioning systems. In this context, components such as batteries, fuel cells, compressors, heat exchangers, mass transfer devices, thermo-electric modules and ejectors are analyzed. Novel control techniques are emerging. The natural refrigerant R744 is the focus of much research. Modern system and CFD simulation methods as well as novel measurement techniques are used. The working group cooperates nationally and internationally with numerous research institutions and companies.

Jaron Buhlmann

Hydrogen-based energy systems,

Liquefaction of hydrogen,

Integration of cryogenic hydrogen storage systems into mobile fuel cell systems

Linda Geva

Fuel cell systems

Jan Friedrich Hellmuth

Thermal management and climate control for battery electric vehicles, Modeling of solid-state battery systems

Fynn Linnenbrügger

Compact heat pumps for households (measurement + simulation), TEN.efzn

Frank Rachow

Trustworthy machine learning models using the example of neural ordinary differential equations

Aike Tappe

Hydrogen-based energy systems,

Liquefaction of hydrogen

Jakob Trägner

Fuel cell stacks and systems incl. degradation

Henrik Waßmuth

Thermal management of hydrogen refueling stations

Alexander Busch

Safety of battery systems

Steffen Heinke

Modeling of PEM fuel cell stack and system, thermal management in fuel cell vehicle, H2 fueling station systems.

Jonas Hielscher

Compact heat pumps for households (measurement + simulation), TEN.efzn

Magnus Lenger

Hydrogen-based energy systems,

Liquefaction of hydrogen,

Integration of cryogenic hydrogen storage in mobile fuel cell systems.

Michael Meltzow

Membrane humidifiers in fuel cell systems;

High-Temperature Heat-Pumps

Andreas Schulte

CO2 supermarket refrigeration systems, global location assessment of refrigeration systems, climate change impact study

Lars Thoben

Hydrogen-based energy systems,

Liquefaction of hydrogen

Niklas Waldmann

MBSE methodologies for HV battery system development; Integration of physics-based simulations into descriptive system models

| Name | Field of Research | |

|---|---|---|

| Daniel Domin | Behaviour of refrigerant-oil mixtures in cold steam processes | d.domin(at)tu-braunschweig.de |

| Florian Hanslik | Water as a refrigerant in compression chillers | f.hanslik(at)tu-braunschweig.de |

| Hamidreza Hassani | Analysis of dynamic process engineering systems, modelling of material data, modelling of wastewater treatment plants | h.hassani(at)tlk-thermo.com |

| Thimo Hug | Thermal management of high-performance vehicles | |

| Florian Jäger | Demand reduction for vehicle air conditioning | florian.jaeger1(at)volkswagen.de |

| Frederik Novotny | Safety of battery systems | f.novotny(at)tu-braunschweig.de |

| Nina Piesch | Elastocaloric heat pump | nina.piesch(at)volkswagen.de |

| Niels Petersen | Modelling of PEM fuel cell stacks | n.petersen(at)tu-braunschweig.de |

| Henrik Schatz | Neural networks in the control of thermal management systems | h.schatz(at)tlk-thermo.com |

| Finn van Ginneken | Influence of degradation on battery safety | f.van-ginneken(at)tlk-thermo.com |

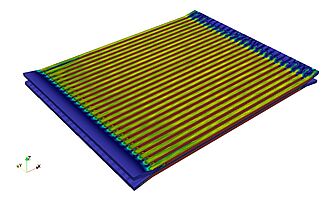

| Torsten Will | Filling quantity in plate heat exchangers | torsten.will(at)ise.fraunhofer.de |