DLR - Institute of Aerodynamics and Fluid Mechanics

DLR - Institute for Aeroelasticity

DLR - Institute for System Dynamics and Control Engineering

DLR - Institute for Software Methods for Product Virtualization

LuFo VI-2: MuStHaF – Project Number 20A2103D

The MuStHaF research consortium, led by Airbus in collaboration with the German Aerospace Center (DLR), the technical universities of Braunschweig and Clausthal, and the company Volz Servos, focuses on application-oriented research and development aimed at designing a next-generation flap system for future short- and medium-haul aircraft. The project’s overarching goal is to support the development of a highly efficient wing design that contributes significantly to reducing fuel consumption and harmful emissions—key objectives aligned with the European "Flightpath 2050" initiative.

A core innovation within MuStHaF is the development of a multifunctional, segmented trailing-edge flap system that enables an aircraft wing with increased aspect ratio. This configuration is expected to reduce induced drag considerably and thereby achieve notable gains in fuel efficiency. The project takes a comprehensive systems approach, targeting not just aerodynamic performance but also integration of actuation, sensing, and control systems to meet the technological and regulatory requirements for future aviation.

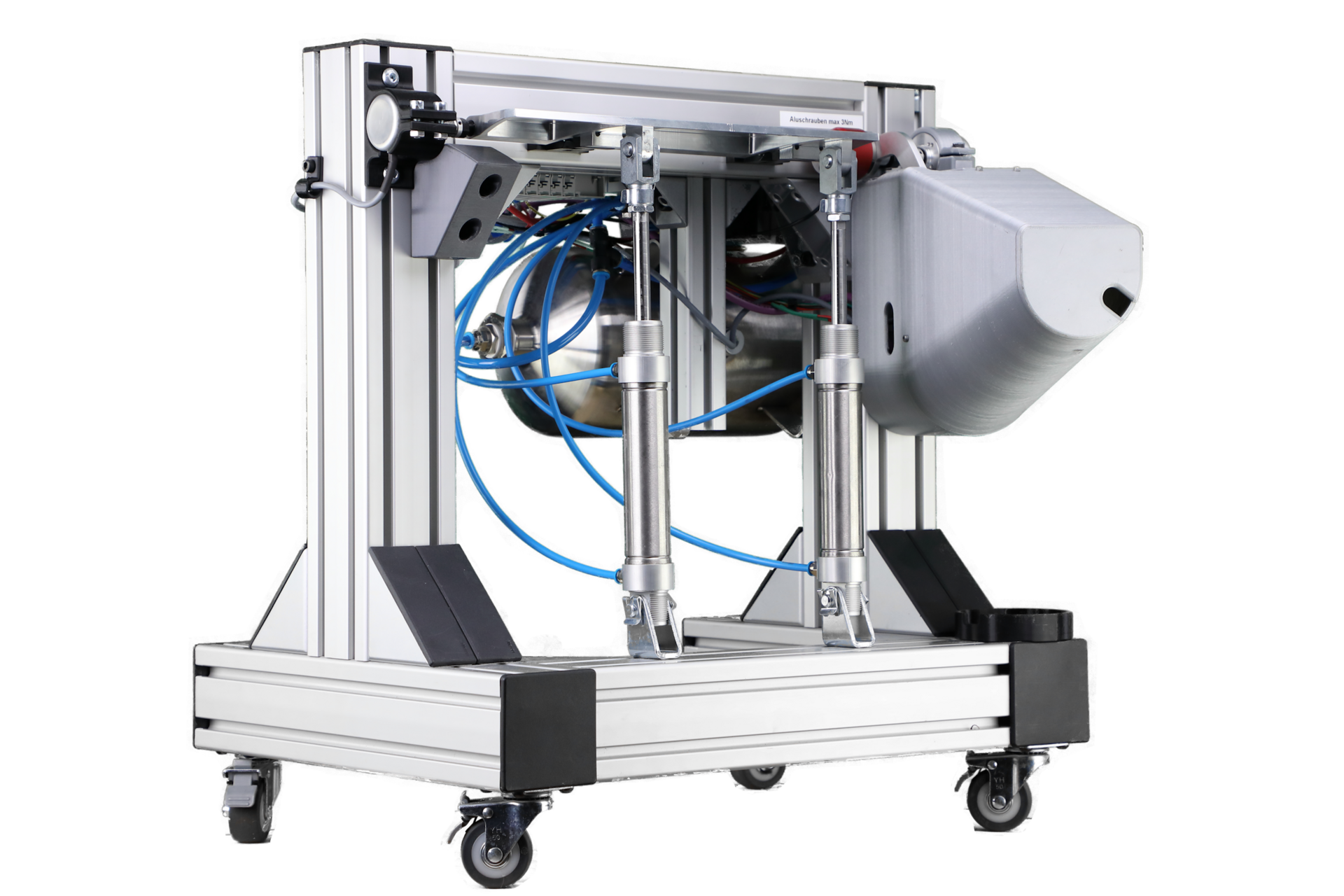

The Institute of Mechanics and Adaptronics (IMA) plays a central role in multiple technical domains. These include system analysis, the development of "Smart Sealings," component design, and the construction of a validation test rig. One of the key contributions is the design and development of a wing bending test bench to simulate in-flight wing loads. This enables pre-flight functional testing of the flap system under realistic deformation conditions, supporting both system identification and the design of flutter control mechanisms.

In the field of Smart Sealings, IMA is developing novel sealing solutions tailored to the segmented flap system. Due to the demanding aerodynamic and mechanical requirements—such as high flap speeds and deflection angles—composite-based sealing elements with directionally optimized stiffness characteristics are being investigated. These aim to bridge the inter-segmental gaps effectively while minimizing aerodynamic losses.

Additionally, TUBS is designing structural inserts for the flap-body interface that are embedded during laminate fabrication. These inserts are intended to distribute mechanical loads uniformly into the composite structure without introducing stress concentrations or adding significant weight.

Further support for flight testing includes the implementation of fiber-optic OFDR sensors to monitor strain states during operation, and the execution of modal analysis on the flight-ready flap assembly, which contributes to the airworthiness certification of the test aircraft.

Altogether, MuStHaF represents a highly integrated technological initiative that brings together innovative aerodynamic, structural, and control system solutions to advance next-generation aircraft efficiency.