Basic Funding

Additive manufacturing of sensors from conductive thermoplastic polymers is a promising field with potential applications in the areas of structural health monitoring and soft robotics, among others. Although the applicability of additively manufactured sensors has already been demonstrated in the literature, there are so far no methods describing how such sensors should be designed and manufactured considering the process parameters. The aim of this project is to develop a model-based design methodology for additively manufactured resistive sensors. This method enables the development of sensors taking into account the restrictions and potentials of the material extrusion manufacturing process.

The development of this design method consists of four phases, which can be roughly divided as follows: material, process, geometry, and formulation and validation of the complete design method.

In the first phase, the resistance properties of the unprocessed conductive composite material (filament) are determined experimentally. This is done to determine the properties of the raw material independently of the influences of the additive manufacturing (AM) process parameters and the mesoscale porosity typical of AM components. In parallel, the melting process parameters for successful extrusion of each material are determined experimentally.

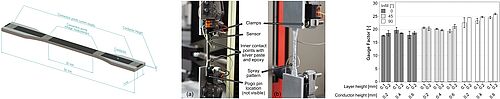

In the second phase, the influences of the AM process parameters are determined. For this purpose, parts with different conductive materials are produced and AM parameters such as layer height and infill pattern orientation are varied. The data from these experiments are used in a multiscale multifield model, with which the electromechanical behaviour is mapped by the mesostructure and the material behaviour of the additively manufactured base material.

In the third phase, the influences of geometric variations of the sensor are investigated. For this purpose, embedded sensors with different layouts, e.g., several meanders, are manufactured and characterised under different load conditions. The experimental data are used to formulate a reduced multifield model based on a phenomenological approach. This model is used to describe complex meander structures.

In the fourth phase, a surrogate model based on physically informed neural networks is developed. Here, the training data is generated with the reduced model, which was previously calibrated with the multiscale model. The surrogate model is calibrated and validated together with the reduced and the multiscale model using the experimental data from the previous phases.

Finally, a model-based design methodology is formulated that combines the findings from the previous phases with product development methods.