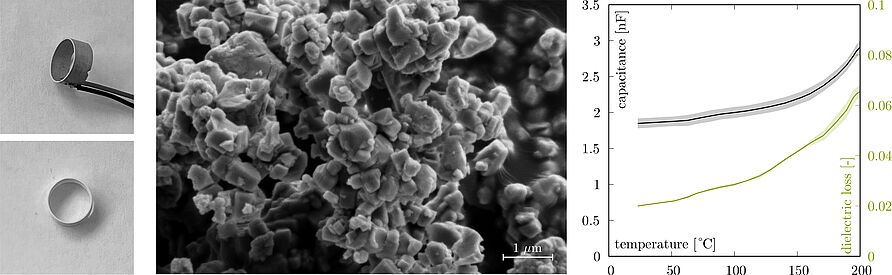

Piezoceramics are smart materials widely used in industry for ultrasonic applications and precise micromotion. However, the widespread use of standard two-dimensional geometries (disks, rings, plates) can limit their efficiency. Optimizing the geometries of piezoceramic transducers could potentially improve their performance. The goal of this study is to enhance piezoceramic slurries for three-dimensional (3D) printing using ultraviolet (UV) light. This will allow for the production of complex geometric, high-density piezoceramic components. The primary objective is to develop a low-viscosity, high curing depth ceramic slurry that maximizes piezoceramic concentration. The methodology involves formulating a slurry containing 76.7 wt.\% potassium sodium niobate (KNN) piezoceramic powder, combined with two monomers with high refractive indices that were selected for their excellent curing properties and compatibility with 3D printing. The study details the selection of materials, preparation of the slurry and the 3D printing process. It is then followed by the characterization of the quality of the manufactured parts, the sintered microstructure, and the performance metrics. The results demonstrate that the developed slurry efficiently prints high refractive index ceramics in 3D, which could potentially offer improved transducer performance compared to conventional two-dimensional geometries. This work provides a foundation for qualitative comparisons with existing piezoceramic manufacturing techniques.

R. Mitkus, M. Böl

On the manufacturing of potassium sodium niobate piezoceramics with low viscosity slurry via digital light processing using high refractive index monomers

The International Journal of Advanced Manufacturing Technology, in print (2025) [Link]