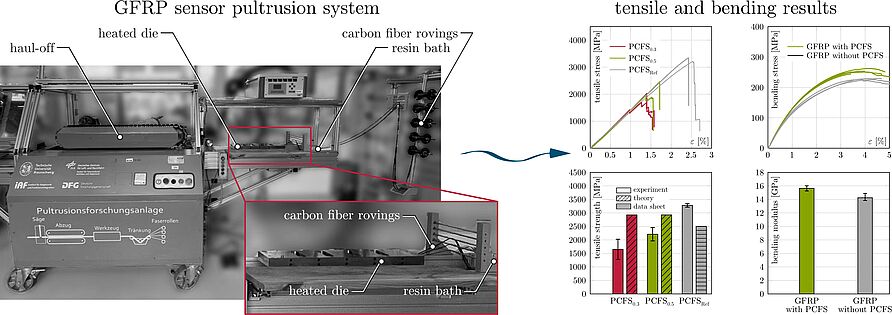

Carbon fibers are electrically conductive and can be used for intrinsic load monitoring through electrical resistance measurement. Using carbon fiber-reinforced polymer parts instead of individual fibers allows for functional integration because it stiffens the structure and simultaneously monitors the load through strain measurement. However, a drawback is that various phenomena occur simultaneously in sensors consisting of multiple rovings, resulting in nonlinear sensor characteristics. The pultrusion process produces straight, aligned fibers, resulting in good linearity and repeatability. This paper presents the manufacturing of sensors of different thicknesses and compares them with reference sensors made from commercially available carbon fiber-reinforced polymer rods. The sensors' sensitivity and linearity are analyzed and compared. All of the sensors exhibited a sensitivity of approximately k = 1.85 and good linearity. The manufactured sensors exhibited properties similar to those of the commercial ones. Finally, the sensors were integrated into a glass fiber-reinforced polymer and subjected to three-point bending tests to demonstrate their ability for functional integration. Although a stiffening function was observed, strain measurements still showed some error compared to strain gauges.

C. Bremer, J. Kube, M. Sinapius, O. Völkerink, Y. Mizutani, M. Böl

Pultruded CFRP sensors for structural stiffening and linear piezoresistive strain sensing in GFRP

Composites Part C: Open Access, 18, 100681 (2025) [Link]