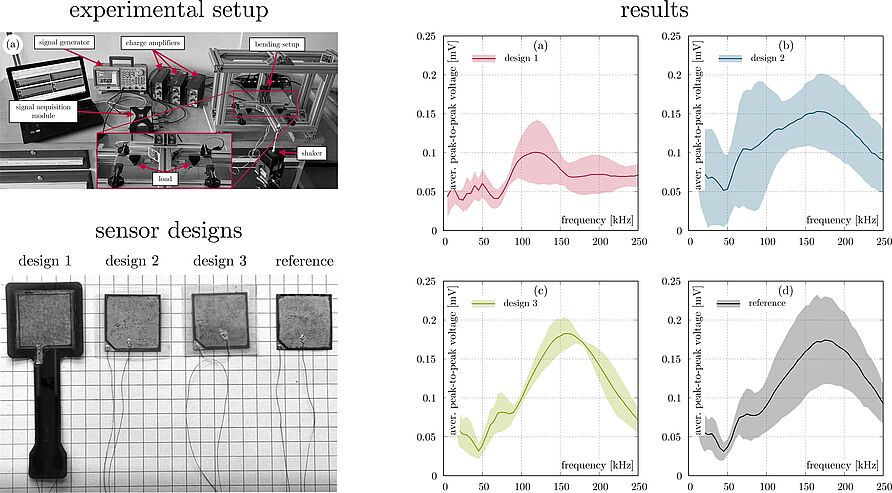

Piezoelectric (0-3) composites typically consist of a polymer matrix that contains piezoceramic particles. They can be used as sensors for structural health monitoring due to their lower acoustic impedance and ability to detect high-frequency waves. These composites have two thin electrodes on their surfaces, and cable connections that require electrical insulation. This insulation increases the durability of the sensor and provides additional protection. One way to achieve this is by encapsulating the sensor in polymer films. However, the sensitivity of the sensor may decrease due to an increase in overall stiffness after encapsulation, so this must also be evaluated. This study experimentally investigates and compares three different encapsulation designs with a non-encapsulated reference sample. The designs include (i) gluing and laminating the sensor onto a pre-prepared flexible printed circuit board, (ii) lamination of the sensor with polyethylene terephthalate, and (iii) lamination with polyetherimide. The sensitivity of the encapsulated sensors to low and high frequency vibrations was evaluated. The results show that an encapsulation sensor with adhesive tape and polyetherimide results in slightly lower sensitivity at lower frequencies, but almost no difference at higher frequencies. These results suggest that the proposed method is suitable for encapsulating sensors for use in structural health monitoring applications.

R. Mitkus, V. Kesminas, M. Böl

Experimental investigation of sensitivity changes during encapsulation of piezoelectric composite materials

Scientific Reports, 15, 31738, (2025) [Link]