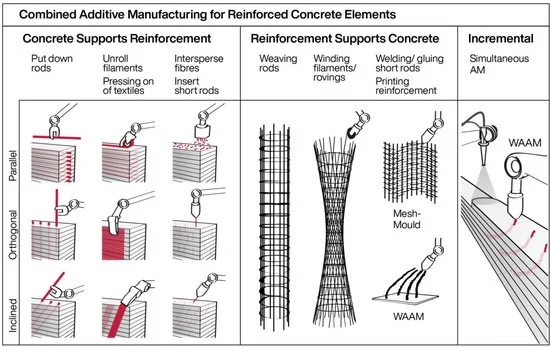

The research described in this paper is dedicated to the use of continuous fibers as reinforcement for additive manufacturing, particularly using Shotcrete. Composites and in particular fiber reinforced polymers (FRP) are increasingly present in concrete reinforcement. Their corrosion resistance, high tensile strength, low weight, and high flexibility offer an interesting alternative to conventional steel reinforcement, especially with respect to their use in Concrete 3D Printing. This paper presents an initial development of a dynamic robot-based manufacturing process for FRP concrete reinforcement as an innovative way to increase shape freedom and efficiency in concrete construction. The focus here is on prefabricated fiber reinforcement, which is concreted in a subsequent additive process to produce load-bearing components. After the presentation of the fabrication concept for the integration of FRP reinforcement and the state of the art, a requirements analysis regarding the mechanical bonding behavior in concrete is carried out. This is followed by a description of the development of a dynamic fiber winding process and its integration into an automated production system for individualized fiber reinforcement. Next, initial tests for the automated application of concrete by means of Shotcrete 3D Printing are carried out. In addition, an outlook describes further technical development steps and provides an outline of advanced manufacturing concepts for additive concrete manufacturing with integrated fiber reinforcement.

N. Hack, M. Bahar, C. Hühne, W. Lopez, S. Gantner, N. Khader, T. Rothe

Development of a Robot-Based Multi-Directional Dynamic Fiber Winding Process for Additive Manufacturing Using Shotcrete 3D Printing

Fibers 2021, 9(6), 39; (2021) [Link]