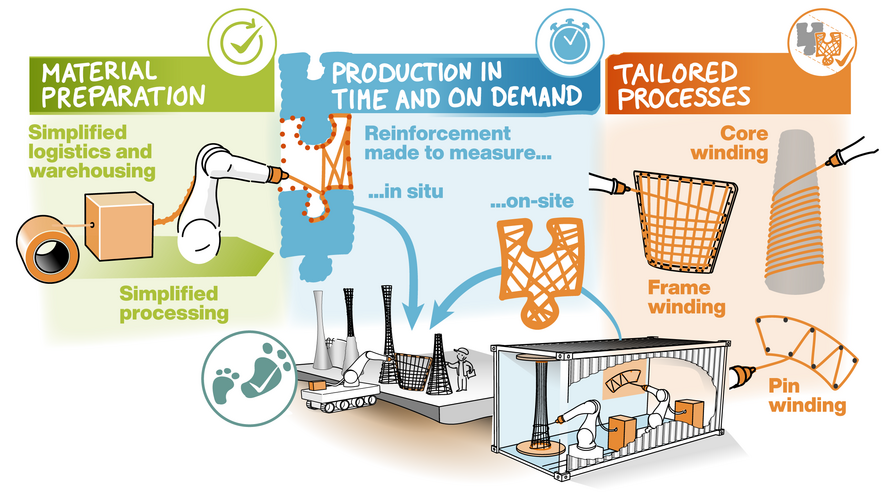

The integration of load path compliant fibre reinforcement structures into additive manufactured concrete elements opens up new potential in the field of construction. The new design language made possible by 3D concrete printing requires reinforcement structures to be provided in a highly individual shaped manner. Digital and robot-based production processes make it possible to produce on-site, on demand, fully automated and just-in-time. In this paper, a concept for an on-site ready fibre reinforcement production is presented. Based on previous works a Dynamic Winding Machine (DWM) for the on-demand production of individualizable reinforcement strands is developed. The concept and technical functionalities of the machine are presented in detail. The functionality is validated based on the production of single reinforcement bars as well as the production of entire, additively manufactured and reinforced concrete structures. With an industrial robot and adjusted end effectors, freely shaped reinforcement structures can be produced automatically. Different concepts for the use of the DWM with mobile robots are discussed. Due to the flexibility of the process, both filigree reinforcement structures, e.g. for use in particle bed printing, and large structures, e.g. for combination with Shotcrete 3D Printing, can be produced.

T. Rothe, S. Gantner, N. Hack, C. Hühne

A Dynamic Winding Process of individualized fibre reinforcement structures for Additive Manufacturing in Construction

Open Conference Proceedings, Vol. 3, (2023) [LINK]