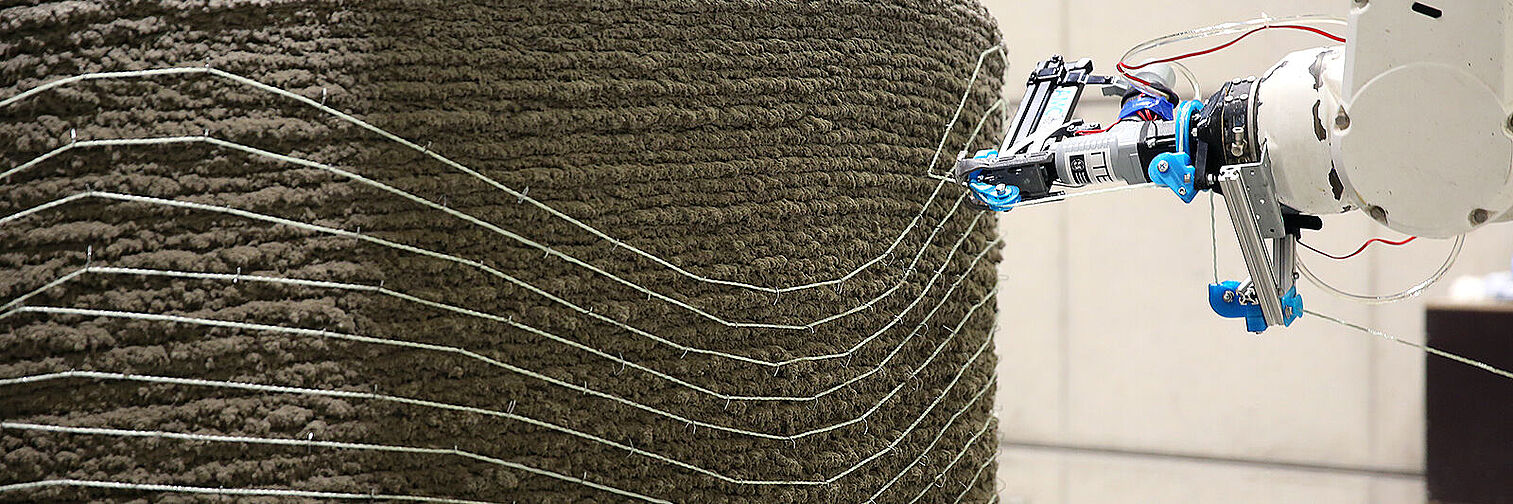

Formgebungen optimieren, Material effizienter einsetzen und damit CO2-Emissionen reduzieren: Die Zukunft des Bauens ist digital gedruckt! Der Sonderforschungsbereich Transregio 277 „Additive Manufacturing in Construction“ (AMC) von TU Braunschweig und TU München will die Digitalisierung des Bauwesens maßgeblich mitgestalten. Materialien, Prozesse und Design werden durch den Einsatz innovativer 3D-Druckverfahren völlig neu gedacht. Dabei stehen für die Forschenden ressourcen- und energieeffizientes sowie nachhaltiges Bauen im Fokus. Die an beiden Universitäten vorhandene exzellente Forschungsinfrastruktur und die sich ergänzenden Expertisen zur Additiven Fertigung im Bauwesen bilden die Grundlage für den Forschungsverbund.

Die Bauindustrie steht vor der drängenden Herausforderung, den Ressourcenverbrauch und ...

Um den traditionellen Stahlbau mit komplexen Geometrien sinnvoll zu ergänzen, ...

Ressourceneffizienz, weniger Emissionen, kürzere Bauphasen, verbesserte Arbeitssicherheit – was wie ...

Wohnungen, Straßen, Brücken – gebaut wird immer. Doch meist mit ...

Die digitale Fertigung im Bauwesen ist trotz einiger Fortschritte noch nicht weit verbreitet. Außerdem steht sie vor Herausforderungen hinsichtlich der Individualität und somit der Komplexität von Bauprojekten. Standardisierte Schalungen und Halbzeuge begünstigen eine ineffiziente Materialausnutzung, was – vor dem Hintergrund des enormen Ressourcenbedarfs im Bauwesen – erheblich zu den globalen CO2-Emissionen beiträgt. Unsere Forschenden wollen die Digitalisierung der Bauwirtschaft vorantreiben und zur Nachhaltigkeit des Bauwesens beitragen. Ziel des Sonderforschungsbereichs TRR 277 „Additive Manufacturing in Construction“ (AMC) ist es, mit Hilfe der Additiven Fertigung Material nur dort einzusetzen, wo es eine Funktion erfüllt und damit den Weg für einen ressourceneffizienten Einsatz von Materialien mit hoher Gestaltungsfreiheit im Bauwesen zu bereiten. In interdisziplinären Teams erforschen Wissenschaftler*innen aus den Bereichen des Bauwesens und des Maschinenbaus komplexe Fragen zu Werkstoff, Verfahrenstechnik, Steuerung, Modellierung, Design und Konstruktion.

Auf 108 Mitglieder ist der Sonderforschungsbereich AMC bis 2023 angewachsen – mit 80 Wissenschaftler*innen, die in 18 Teilprojekten forschen. 32 Institute sind am AMC beteiligt, davon 14 an der TU Braunschweig und weitere 14 an der TU München. Hinzu kommen Wissenschaftler*innen der TU Berlin, der Leibniz Universität Hannover und der TU Chemnitz. Durch die Zusammenarbeit der verschiedenen Institute und Universitäten innerhalb des Sonderforschungsbereichs entsteht ein dynamisches Forschungsumfeld, das die Grundlage für innovative wissenschaftliche Erkenntnisse und technologische Entwicklungen bildet.

Insgesamt haben unsere Forschenden rund 110 wissenschaftliche Publikationen veröffentlicht, 30 internationale Keynote-Speeches gehalten und einige Preise und Awards erhalten, darunter den German Innovation Award 2021, den Iconic Award and German Design Award 2022, Finalist und Special Mention bei der 3D Pioneers Challenge sowie weitere Auszeichnungen für hervorragende wissenschaftliche Arbeiten. Regelmäßig lädt der AMC herausragende internationale Wissenschaftler*innen aus verschiedenen Disziplinen für längere Aufenthalte ein, die die Projektmitarbeitenden mit ihrer Expertise unterstützen. Mit Workshops beim Digitaltag und Zukunftstag sowie LabDays zeigt der AMC Schüler*innen, dass Technik Spaß machen kann und welche Möglichkeiten der digitale Herstellungsprozess für nachhaltige Entwicklungen im Bauwesen bietet.

Sind Sie Vertreter*innen der Presse oder der Politik und haben Fragen zu unserer Forschung? Unsere Wissenschaftler*innen teilen gerne Ihr Wissen und Expertise mit Ihnen.

Prof. Dr. Harald Kloft

Sprecher der Sonderforschungsbereichs TRR277 AMC

Tel.: 0531 391 3571

h.kloft(at)tu-braunschweig.de

Main TRR 277 Pages:

______________________

News

© 2020 TRR277

TRR 277 specific:

Privacy Policy

Disclaimer

Imprint