Funding Agency: DFG

Project Lead : Simon Bahnmüller

Project Summary

The DFG-funded project “Semi-Mechanistic Modelling of Fracture Mechanisms of Engineered Artificial Minerals (EnAMs)” is part of the Priority Programme SPP 2315 – Engineered Artificial Minerals (EnAM) – a geo-metallurgical tool to recycle critical elements from waste streams.

The aim of this research project is to develop a predictive model for the fracture behaviour of complex, artificially engineered multi-component systems (e.g., metallurgical slags) in order to optimise their comminution and, consequently, the selective recovery of critical raw materials.

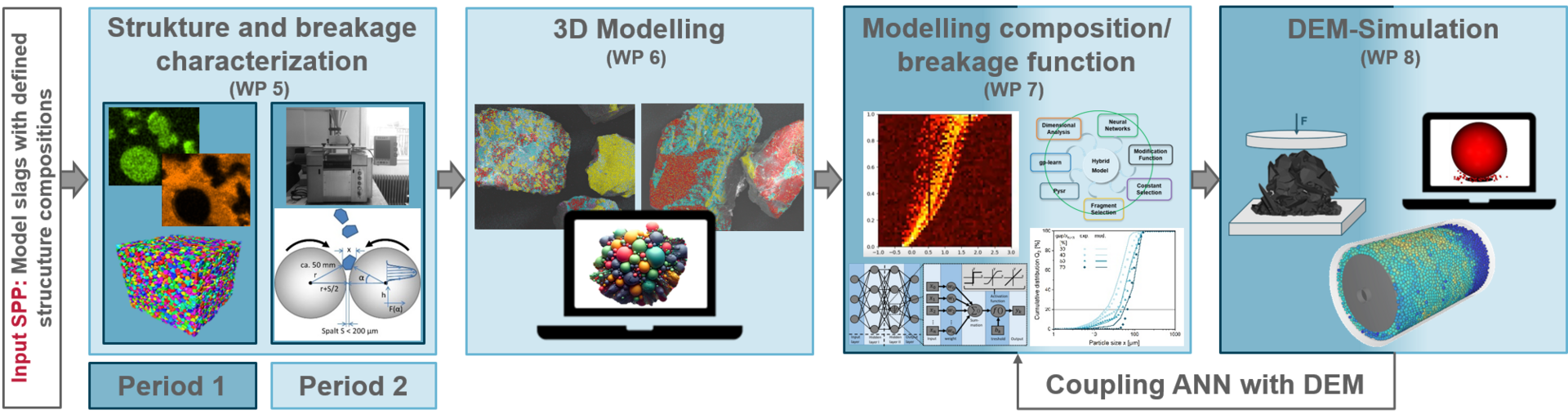

The project combines experimental investigations, numerical simulation (DEM) and data-driven modelling (machine learning). Based on micro-compression tests and two-roller breakage tests as single-particle fragmentation experiments, the fracture behaviour of EnAM particles is analysed as a function of their structure, composition and size.

The objective is to establish a semi-mechanistic fracture model that describes the transition between intercrystalline and intracrystalline breakage and can be transferred to real mineral processing operations.

By linking micromechanics with advanced modelling approaches, the project contributes to the resource-efficient design of recycling processes, particularly for the recovery of lithium, indium and other critical metals from industrial residues.

Objectives and Tasks of iPAT

Project partners