Sponsor: DLR - German Space Agency

Contact person: Dimitri Ivanov

Summary of the overall project:

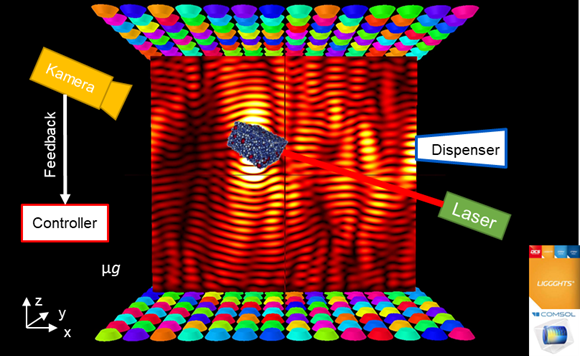

The research project ‘Lev4ISM: Ultrasonic Levitation as a Handling Tool for ISM Processes’ aims to develop an innovative, resource-efficient manufacturing process. To this end, the ultrasonic levitation process will be transformed into a handling tool. This will allow powders, small particles, and resulting components to be manipulated during manufacturing. For the first time, this will allow components to be moved and oriented beyond the wavelength limitation. The system will initially be set up and tested in microgravity conditions, followed by reduced gravity conditions in a subsequent project. An ultrasonic field is generated in a setup consisting of two opposing plates equipped with transducers. In this field, particles can be moved to a target location without contact and fused with levitating particles using a laser. An AI trained with reinforcement learning will control the movement of the particles. The position of the particles is determined by a camera and transmitted to the AI. DEM simulations are performed to obtain sufficient training data.

Goals and tasks of iPAT

Project partners

Dr.-Ing. Christoph Lotz, Institute of Transport and Automation Technology, Leibniz Universität Hannover

Diagram for a substrate-free additive manufacturing process using ultrasonic levitation