Additive manufacturing has seen its increase in popularity in the use for fabricating geometrically complex components, such as multiple-shell structures with integrated functionality. The research project B3.2 investigates to what extent additive manufacturing (AM) technologies, like selective laser melting (SLM), fused deposition modeling (FDM) and stereolithography (SLA) are suitable in the production of suction panels for Laminar Flow Control (LFC). Laminar flow control is a proven possibility to reduce the drag of commercial aircraft. However, the complexity of the system prevents manufacturers from using the LFC technology in serial production. It is believed that AM technology poses the opportunity to manufacture such a complex system economically.

Parts designed for conventional manufacturing processes are usually not ideal for the different AM processes. The benefits of additive manufacturing can especially be achieved with parts designed for the specific printing process. When producing geometrically complex structures using the conventional manufacturing techniques, a significant supplementary effort in the form of post-fabrication tooling is usually required and is strongly related to the complexity of the part that needs to be manufactured. Whereas, in additive manufacturing, the build process is not related to the complexity of the part. The advantages of a fully functional integrated design approach, typical to additive manufacturing, outweigh the increased modeling effort of the complex geometries.

The additive manufacturing of suction panels requires a comprehensive understanding of the 3D printing process. Due to the wide range of thermo-mechanical dependencies and complex physics involved in the printing process, choice of precise process parameters are needed. Inaccurate choice of process parameters can lead to poor surface quality, distortion and porosity, etc. This can further result in the failure of the manufactured part. In order to avoid these defects and facilitate the availability of dimensionally accurate and mechanically stiff parts, numerical studies of the process and experimental analysis of the manufactured specimens, ranging from coupons up to representative modules are necessary.

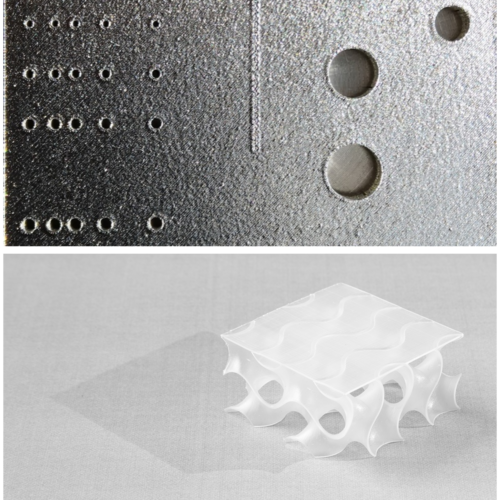

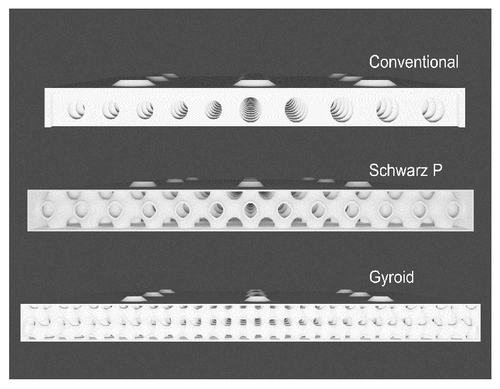

Suction panels for laminar flow control can be divided into two functional units, the porous suction skin and the support structure below. The suction skin should have a continuous porosity to guarantee continuous suction on the whole surface. The support structure has to make sure the suction skin is an aerodynamically smooth surface prevented from waviness or buckling.

The integration of suction skin and support structure using conventional techniques can cause blockage of some holes in the suction skin and subsequently result in the reduction of suction area. Whereas, additive manufacturing allows an integral manufacturing approach of the whole structure, thereby reducing the hole blockage to an absolute minimum.

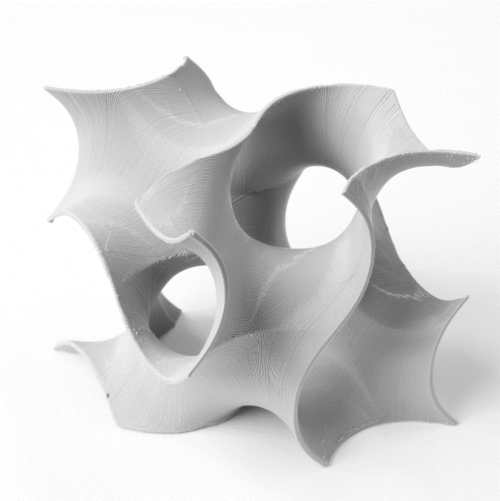

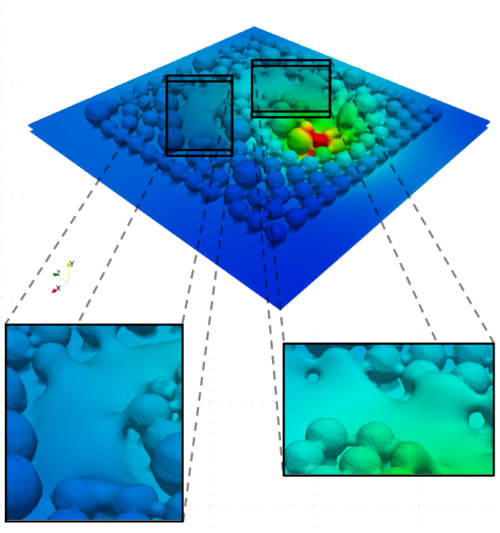

The suction rate on the suction panel is controlled by the pressure difference over the suction skin. The suction skin and the support structure can be used to model a specific pressure drop in the structure itself, allowing to control the pressure distribution in the panel and thus the distribution of the suction rate. Triply periodic minimal surface structures as Gyroids or Schwarz-P can be used in AM as a lightweight yet strong and stiff support structure. At the same time their specific geometry allows a mass flow through the structure in two distinct “channel-systems”. In this project, the mechanical properties of such meta materials are investigated. The obtained reduced order model can be used in B3.1 for the integration in the global structural design of the HLFC wing. The ability of triply periodic minimal surface structures (meta structures) to control pressure drop are investigated by JRG B1 with meta structures designed and manufactured in B3.2. The meta structure approach for the suction panels is compared to a conventional design approach investigated in B3.1 regarding structural and aerodynamic properties.

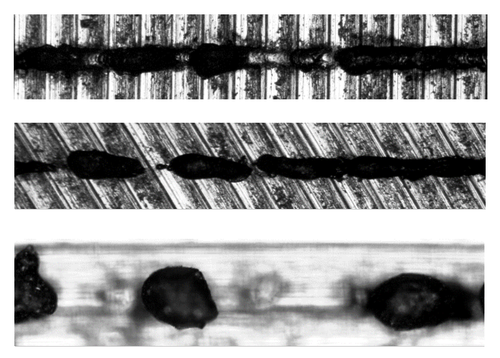

In SLM, the material in its powder form is melted by a moving laser heat source following a user-defined build plan. The process parameters e.g. laser power, scanning velocity of the laser beam, etc., strongly influence the flow behaviour of the molten metal and the subsequent re-solidification. This can influence the quality of each individual layer of the build process and further affect the surface topography of the manufactured part and is important to be studied in full detail.

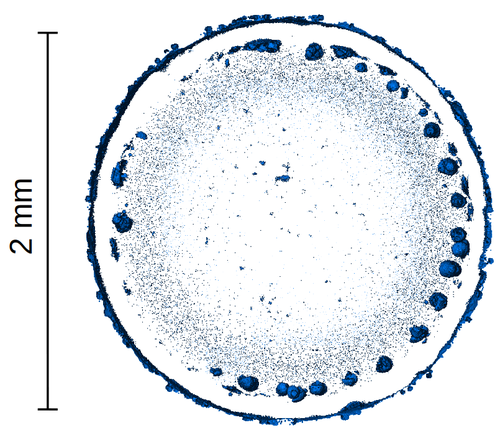

In order to enable sufficient air suction into the meta structure, the quality of the holes in the outer suction skin is of great importance. To facilitate the fabrication of these sub-millimeter size holes precisely, sufficient knowledge of the SLM process at the powder-scale is required.

The complexity of the manufacturing process can make experimental studies on a single laser path level challenging. Therefore, it is necessary to supplement these studies with accurate numerical models to obtain a better understanding of the process and its parameters. In addition to the quality of the hole, a good surface quality of the outer skin is to be ensured. The surface quality can be influenced by the different SLM process parameters and are investigated in this project.

The 3D printed metallic suction skin is invesigated by JRG B1 to study the pressure distribution across the holes. This interaction with JRG-B1 can further expand the knowledge required for the efficient design and manufacturing of suction panels.

Department of Mechanical and Process Engineering

+41 44 632 51 45

Prof. Dr.-Ing. Michael Sinapius

Institute of Adaptronics and Function Integration

+49 531/391-2640