The Working Group Battery Process Engineering at the Institute for Particle Technology (iPAT) deals with procedural aspects of electrochemical storage technologies, from basic research to process and manufacturing technology of the industrial production of electrodes. The thematic focus can therefore be well captured by the term “battery process technology.” „Battery LabFactory Braunschweig (BLB)“

At the beginning of the classical battery process technology the powdery components are mixed and dispersed to obtain a suspension suitable for coating. The suspension consists of various active materials, inactive components (conductive carbon black, conductive additives, binders) and a solvent. The aim of mixing is to homogeneously mix and pre-structure the powdery components. The dispersion process serves to disperse the powders within the solvent and to specifically disperse the conductive carbon black particles in order to achieve defined power and energy properties inside the cell.

After the production of the suspensions for anodes and cathodes, these are applied to conductive films with layer thicknesses of 10-20 µm using a wet coating process via an application tool. These composite films already represent an electrode which is further processed in following process steps. In the industrial series production of electrodes, a continuous slot die process is used, which is usually followed by a convection drying step. The wet film thickness ranges from 150 to 300 µm and results in a dry film thickness of more than 100 µm. Compared to coating, drying represents the speed-determining production process. Typically, the drying time is approx. 1-2 minutes. The duration depends in particular on the thickness of the coating, the solids content of the suspension and the solvent used. At the end of these processes, several hundred meters of so-called electrode coils are wound onto a coil core and are ready for calendering.

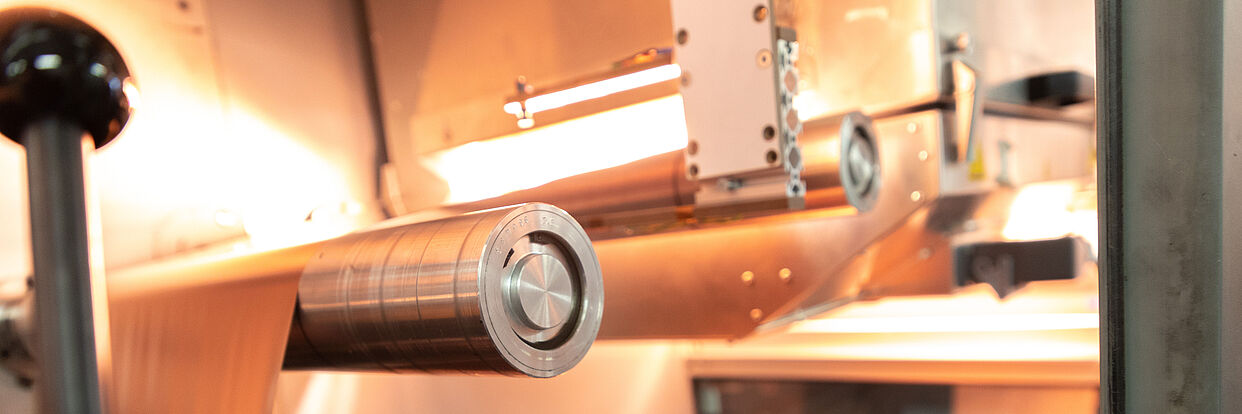

Continuous roller compaction is referred to as calendaring. This involves calendering the previously produced electrodes to a specific target density. Structural properties such as the porosity, adhesive strength or conductivity of the electrode and thus the electrochemical performance are significantly influenced. In addition, a homogenization of the layer thickness is achieved, which is of great importance for the subsequent stacking process.

Within the production of lithium-ion batteries, cell construction with the previously manufactured electrodes and electrochemical characterization are at the end of the process chain. This shows that the total of all individual, previous process steps has an influence on the electrochemical performance of an electrode in a battery cell. The electrochemical characterization mainly includes stress tests during charging and discharging of the cells. These test cycles show how good and how much electrical charge can be stored and extracted again in the battery depending on the level of the flowing electrical current. The slow diffusion of lithium at high current densities limits the inter- and decalcification processes of lithium into the active materials. At the same time, high electrical conductivity must be ensured. These limiting factors have to be identified and minimized by suitable methods within the process chain.

The increasing demand for lithium-ion batteries (LIB), caused by the growth of the e-mobility industry, has created the need for a sustainable recycling process for used batteries Production committees. Ideally, the battery materials should be recovered in the highest quality with minimum effort in order to realize their direct re-use as battery materials. Especially in the field of valuable battery active materials, such a procedure is economically and ecologically beneficial. For this reason, an intelligent recycling process for all valuable battery ingredients is being developed in the battery process engineering working group.

During the use of a battery, various abusive external stresses, or even production errors can cause unwanted reactions within the cell, which can abruptly convert the stored electrical energy into thermal energy and result in a thermal runaway. Therefore, safety investigations are carried out in order to better understanding the processes of the thermal runaway as well as to increase the significance and reproducibility of the current test procedures and to streamline them through standardization, so that the conditions for testing and approval in the lead markets (China, EU, USA) can be harmonized.

The performance of a lithium-ion battery depends very much on the mechanical properties of the individual electrodes. Not only the properties of the entire electrode must be considered, but also the behavior of individual particles. The Discrete Element Method (DEM) offers the possibility to simulate the mechanical behaviour at particle level to understand processes within the electrode which are not or only partially accessible by experiments. The simulation represents the mechanical stress within an electrode, which is caused by volume expansions during lithium intercalation, as well as the behaviour during manufacturing processes such as calendering or winding of a round cell. Individual areas within the electrode can be studied separately and predictions about the adhesion of the particles to each other and to the substrate are possible.