To fulfill the increasing demand for lithium-ion batteries with higher energy densities, approaches with silicon as a promising active material are under investigation. A disadvantage of the use of silicon is the fact, that silicon, due to its large volumne fluctuation during the charging and discharging phase, leads to a reduced cyclelife. The volume fluctuation leads to an increased SEI formation and therefore to a higher irreversible loss of lithium. In order to reduce this loss of lithium and to make the use of silicon sustainable, various process technologies are being investigated with the aim of increasing the available amount of lithium in the battery.

The aim of the project is to establish a comprehensive, continuous electrochemical process for the prelithiation of electrodes, which compensates the consumption of lithium during the cyclization of the cell. The advantage of this innovative process would be that silicon could be mixed in larger quantities, which ultimately results in both a higher energy density and a more stable cyclelife.

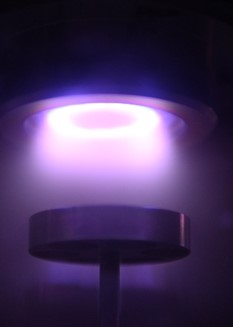

For the prelithiation, various process techniques are evaluated. The ifs deals with a discontinous process, in which a thin layer prelithiation is applied to the electrode as a sacrificial top coating, by using PVD (physical vapor deposition). This is intended to generate a lithium-reservoir that can be accessed during the first charge and discharge cycle.

German Federal Ministry of Education and Research

Partners