Range, quick charge, lifetime and cost of cover current lithium-ion batteries in electric vehicles currently only partially with the requirements of users and are therefore major barriers to electromobility. Therefore need to significantly improve these application properties and further cost reductions are achieved. Possibilities insist on the above property improvements with regard to the use of new so-called high-capacity Materials for the anode contact and their combination with high energy materials in the cathode contact of a battery cell. In terms of cost, new manufacturing processes, who refrain from energy-intensive and therefore expensive steps or significantly shorten the manufacturing process, big Reduction potential

Objective of the project It is based on advanced active and passive materials the production of a so-called particulate active material Binder-carbon black composite material for high-efficiency electrode processing to explore. Economically sustainable material and Process concepts should be investigated and established in perspective, enable a short-term market entry can. In detail, a material and component side tuned high-energy battery cell to be developed. By improved formulations and process technologies are said to extend the life be further increased. It's supposed to be a process for processing high-energy materials to composite particles as well.

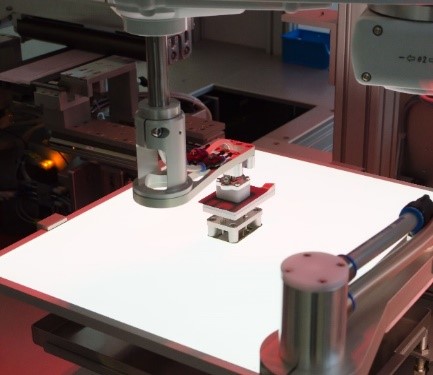

The cutting of electrodes with ultrashort pulsed laser radiation is to be investigated here. In particular, the development of the laser cutting process for the reduction of the thermally influenced area along the cutting edge of electrodes. The heat-affected zone should be as small as possible, since this area can negatively influence the capacity of individual electrodes and thus of entire cells. Ultra-short pulsed laser radiation enables a nearly cold ablation process. Thus, laser-based cutting can be realized without negative thermal influence.

PTJ – Project Management Jülich, Forschungszentrum Jülich GmbH

Partners